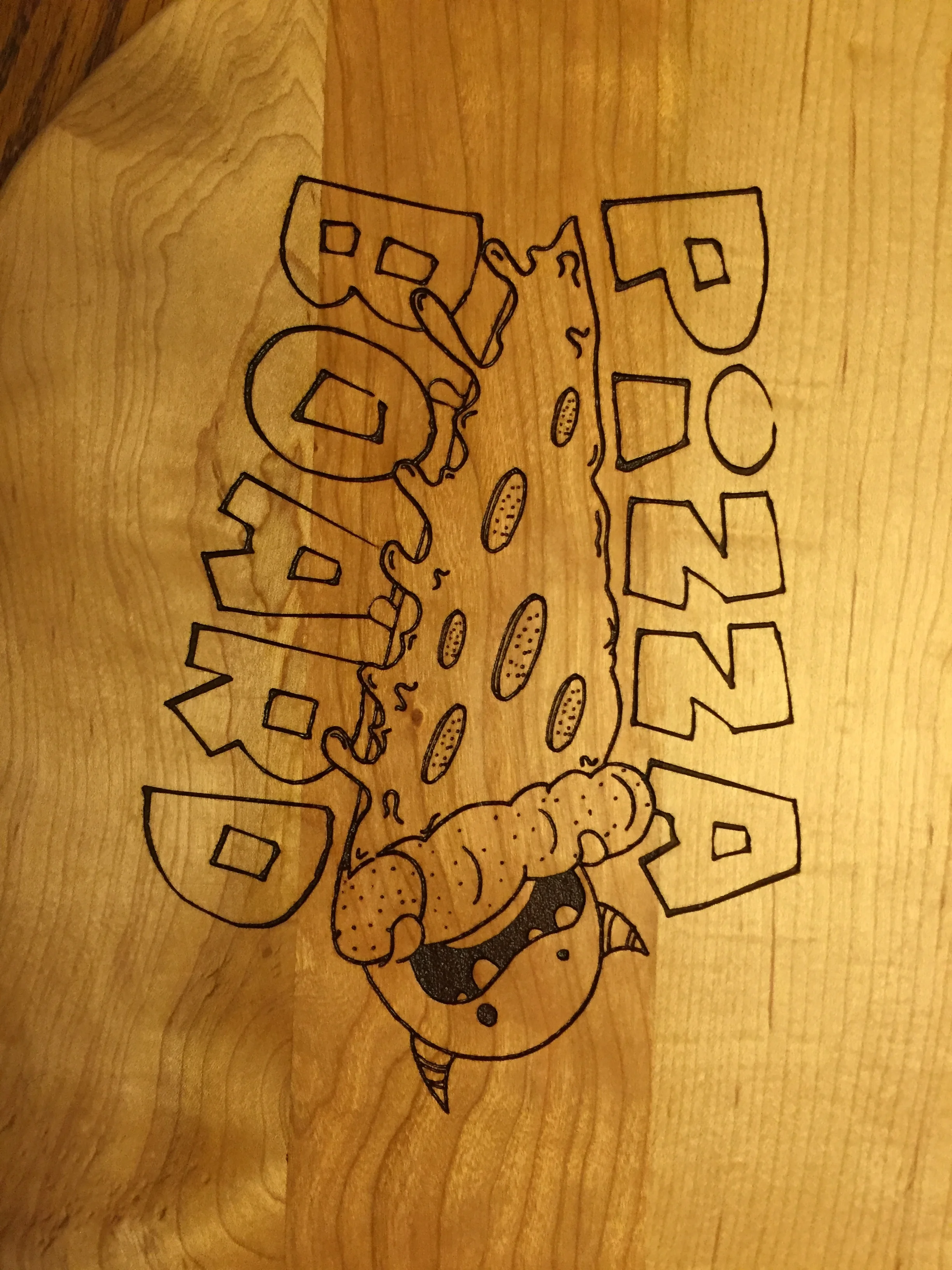

Pizza Board - Pizza Peel

We recently acquired a pizza steel, which is nothing more than an overpriced hunk of steel that you put in your oven. It does make pretty darn good pizza though. Anyways, with the addition of the pizza steel to our kitchen set up, we started throwing somewhat regular pizza making parties. We had an aluminum pizza peel/paddle for transferring the pizzas into and out of the oven, but the raw dough was getting stuck to it when sliding the pizza on to the steel. A wooden peel has less of a problem with this than the aluminum version. Thus, a new project was spawned.

Required Resources: 90 minutes hours, $10

Size: 22" x 16" x 0.5"

Materials: Hard Maple, Cherry, Titebond IIII

Finish: Howard'd Butcher Black Conditioner

Tools: Miter Saw, Band saw, Planer, Jointer, Laser Cutter, Belt Sander

New Techniques: This project wasn't particularly novel, technique wise, but it was one of the first times I challenged myself to a speed build. Alexa and I were struggling with our aluminum pizza peel and we talked about making the wooden peel. After dinner, I took 45 minutes to scrounge up some wood and did the first glue up. The next evening I took the glued blank to the band saw, and then to the sander to fine tune the profile. Inspired by my enthusiasm for making the pizza peel, Alexa designed a logo the night before, to be etched on the peel. Another 20 minutes to laser the board, and a coat of butcher block conditioner, and the Pizza Board was ready to go.

Lessons Learned:

When Possible, Use a Stencil: In the name of celerity, I free handed the profile of the pizza peel. As it turns out, I am not as talented of an artist as Alexa is and the profile I drew and cut out was rather asymmetric and misshapen. I spent an additional 20 minutes on the belt sander to get the board looking somewhat more even. Even then it had a noticeable bias toward one side. Next time, I will take the time to sketch something up in SolidWorks and print out a 1:1 sketch to use as a stencil. The 10 extra minutes of effort up front has the potential to save me 20-30 minutes of cleaning up a design/profile when drawn free hand.